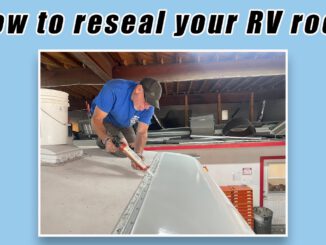

Applying sealant to your RV roof, especially a self-leveling silicone sealant, can significantly extend the life of your roof and protect it from leaks and water damage. Here’s a detailed step-by-step guide on how to apply the sealant properly to ensure effective coverage and a long-lasting seal.

Materials needed

- Self-leveling silicone sealant (check the manufacturer’s website for compatibility with your RV roof material)

- Caulking gun (if using a tube of sealant)

- Painter’s tape or masking tape

- Clean rags or towels

- Isopropyl alcohol (for cleaning)

- Rubber gloves

- Ladder or step stool for easy access to the roof

- Putty knife or sealant smoothing tool (optional)

- Masking paper (optional, to protect nearby areas)

Step 1: Clean and prepare the roof surface

Before applying any sealant, it’s crucial to ensure the surface is clean and free of dirt, debris, and old sealant. Any contaminants on the roof will prevent proper adhesion.

- Clean the roof: Use a hose or a pressure washer to rinse off dirt and debris from the RV roof. Then, use a cleaning solution and a scrub brush to remove any grime or mildew.

- Dry the surface: Make sure the roof is completely dry before applying the sealant.

- Remove old sealant: If you’re resealing or replacing old sealant, use a putty knife or scraper to carefully remove any existing sealant, ensuring a clean surface for the new product.

- Clean with alcohol: Wipe down the area where you will apply the sealant with a cloth soaked in isopropyl alcohol. This removes any residual oil, dirt, or other contaminants that could affect the sealant’s bond.

Step 2: Mask off areas not to be sealed

If you’re using a silicone sealant, for precision application use painter’s tape or masking tape to protect surrounding areas that you don’t want to seal. This ensures a clean and neat application, especially when dealing with seams or edges.

Step 3: Prepare the sealant

- Load the caulking gun: If you’re using a tube of self-leveling silicone sealant, insert the tube into a caulking gun. Cut the tip of the nozzle at a 45-degree angle to the desired size. The opening should be wide enough to allow a controlled bead of sealant to flow out. This is the caulking gun I recommend.

- Test the sealant: Before applying to the roof, squeeze a small amount of the sealant onto a disposable surface (like a scrap piece of cardboard) to ensure that it flows out easily and is ready for application.

Step 4: Apply the sealant

- Start at the edge: Begin applying the sealant at one edge of the area to be sealed (e.g., along seams, vents, or edges where the roof meets other components).

- Apply a continuous bead: Hold the caulking gun at a consistent angle (about 45 degrees) and gently squeeze the trigger as you move along the area to be sealed. Aim for a continuous bead of sealant, making sure the entire seam or crack is covered.

- Self-leveling sealant: Self-leveling silicone sealant is designed to spread out on its own once applied, so it’s important to apply enough sealant to cover the area fully, but not too much to create puddles. Make sure the sealant flows into the seam or crack and spreads evenly across the surface.

Watch my demonstration in the video below.

Step 5: Smooth the sealant (optional)

If you find that the sealant is not spreading as evenly as you’d like, or if you want to make sure it’s applied perfectly, you can use a smoothing tool or a putty knife to smooth the surface.

Wet the smoothing tool with a little water or soapy solution and gently smooth the sealant across the surface. This helps ensure even coverage, fills any gaps, and creates a smooth, clean finish.

Step 6: Remove the painter’s tape

After the sealant has been applied, carefully remove the painter’s tape or masking tape. Do this before the sealant begins to set, as it will help prevent the sealant from pulling away with the tape when dried.

Step 7: Allow the sealant to cure

- Curing time: Self-leveling silicone sealant typically requires around 24 to 48 hours to cure completely, but check the manufacturer’s instructions for specific cure times. During this period, avoid any contact with the sealed areas to ensure the sealant forms a strong, durable bond.

- Environmental conditions: Ensure the temperature is within the recommended range (usually between 40° F and 90° F), and avoid applying the sealant during rainy or extremely humid conditions, as this can impact the curing process.

Step 8: Inspect the application

Once the sealant has cured, inspect the application to make sure the entire area has been sealed properly. Look for any gaps or areas that may have been missed or areas where the sealant might have pulled away.

If needed, apply an additional layer of sealant to areas that didn’t seal properly. Ensure these areas are clean and dry before applying.

Step 9: Maintenance and future inspections

- Check regularly: Inspect the sealed areas periodically, especially after heavy rains or harsh weather, to ensure that the sealant has maintained its integrity.

- Touch-ups: If you notice any cracks or areas where the sealant has started to peel, perform touch-ups as needed to maintain a waterproof barrier.

Final thoughts

Applying self-leveling silicone sealant to your RV roof is an effective way to prevent leaks and maintain a secure, water-tight roof. By following these application steps, you can ensure the sealant adheres well, dries evenly, and provides lasting protection.

Be sure to follow all manufacturer guidelines and use the correct sealant for your roof material, as different materials may require different sealants. Properly applied sealant will help keep your RV in excellent condition and prevent costly water damage down the road.

More from Dustin

Make sure you check out my website, California RV Specialists, and our YouTube channel for more helpful information, and see our published articles on RVtravel.com and other social media pages.